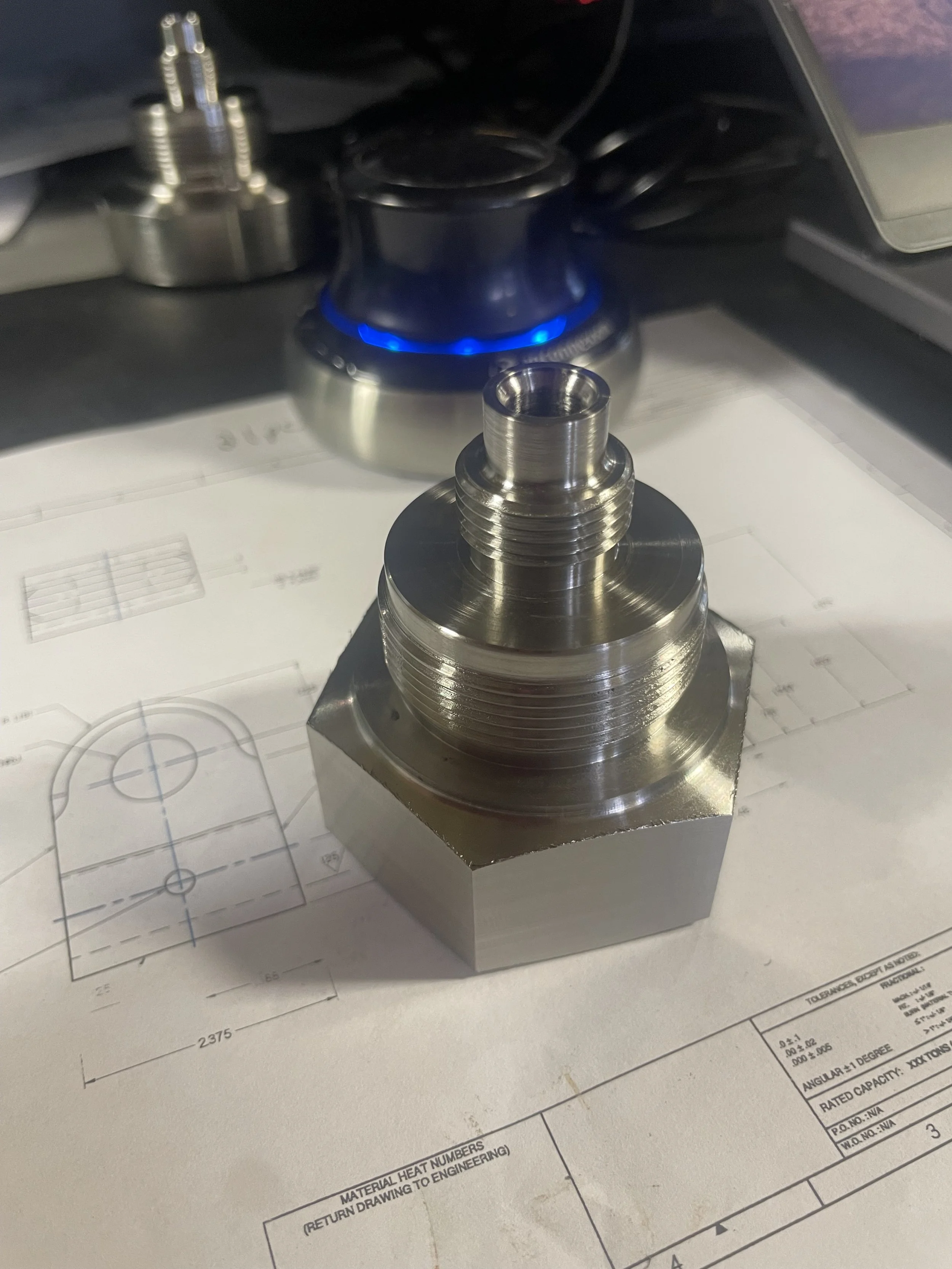

Valve & Oilfield Component Machining

AR Premier Machine specializes in the precision machining of valves and oilfield components from solid billets. With over 10 years of experience, we have built strong expertise machining stainless steel valve bodies and critical flow-control parts that require tight tolerances, complex internal features, and consistent repeatability.

We are also expanding our capabilities in high-performance alloys such as Monel, Inconel, and other nickel-based materials, supporting oil & gas applications where corrosion resistance and material integrity are critical. Our focus is on reliable processes, accurate machining, and on-time delivery for both prototype and production work.

OUR SERVICES

AR Premier machine specializes in CNC precision machining for customers that require regular or periodic production of custom machined components.

CNC Turning

CNC Milling

CNC Multi-Axis Machining

Sawing

CNC Boring

CNC Threading

CNC Knurling

CNC Drilling

CNC Broaching

High Volume Production Machining

CNC Deburring

CNC Engraving

Machining of Steel, Stainless Steel, Exotic Alloys, Nickel Alloys, Brass, Aluminum, Plastic, and Etc.

Outsourcing to 3rd Party Sources for Heat Treating, Coatings, NDT, EDM, Deep Hole Drilling, Honing, Grinding, Laser Cutting, Water Jet Cutting, and Etc.

Materials Sourcing & Purchasing

Professional Engineering Review

Onsite Warehousing for holding your inventory in stock and supplying as needed

Inventorying your hard to find material or semi-finished parts and finish machining as needed

Manufacturing and supplying your critical path requirements

On Demand Worldwide Shipping